Label printing dispenser for labeling with variable data

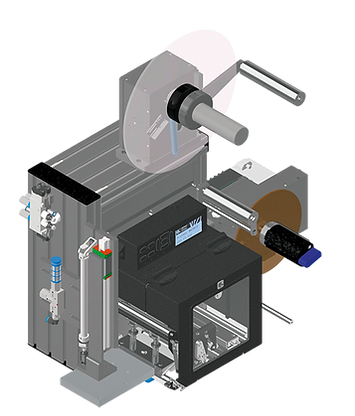

Basic concept of the label printing dispenser:

Marking variably, quickly and reliably

The EDS label printing dispenser is designed for industrial use and enables precise,

reliable and fast labeling of products and packaging. The standard system consists of a print module, label winder and unwinder and the controller. With different applicators and label transfer modules, the label dispenser can be used for almost any application. The systems are available as 4" or 6" versions and as (right) RH and (left) LH devices.

The label pre-warning, which is already included in the standard module, informs the operator in good time about the pending label change. The modular design and the robust design were the focus of the development of the system. Since all extension modules and applicators are pluggable, the systems can be expanded at any time in a modular manner or completely adapted to another applicator system.

Label printing dispenser - EDS

Label printing dispenser - EDS with pneumatic transfer

Available application modules and accessories:

applicators:

-

50mm | 100mm | 200mm | 250 mm tamp-on applicator (4.5 bar - up to 75 N)

-

300 - 1200 mm tamp-on applicator (6 bar - greater than 75 N)

-

90° swivel applicator (front | back)

-

Stroke-Turn Applicator

-

Swiveling Stroke Applicator

-

Corner applicators (corner wrap for front | back)

-

Special applicator for very small labels (2 pneumatic movements)

-

Flag applicator for round materials

-

tandem | Telescopic applicators - compact design with a long range

-

suction tape applicators

donation edges

Dispensing edge with pressure roller | Squeegee brush (dispensing speed identical to printing speed)

Motor-driven dispensing edge (dispensing speed independent of the printing speed - max. 60m/min) with optional speed synchronization

All of the above applicators are optionally available with a blowing function (distance sensors or spring-loaded vacuum plate).

print modules

You are completely free in the selection of the print modules:

-

Zebra ZE500-4 (standard 4")

-

Zebra ZE500-6 (Standard 6")

-

CAB PX Q4 | CAB PX Q4.3

-

CAB PX Q6.3

-

SATO S84-EX

-

SATO S86-EX

-

Novexx DPM

-

Novexx PEM

-

datamax o'neill A-4XXX

-

datamax o'neill A-6XXX

-

TSC PEX-1120 | PEX-1220

-

TSC PEX-1130 | PEX-1230

-

TSC PEX-1160 | PEX-1260

Add-ons:

fixed | mobile tripods in different heights

height and adjustment units

Side mount adapter

Product light barrier KIT

Beacon KIT

Display relocation KIT for outdoor installation

1D barcode scanner KIT

1D/2D barcode scanner KIT

Specifications - EDS

variants

4" | 6"

handedness

L/R

printing process

Thermal Transfer |

thermal transfer direct

OEM print engines

4” | 6" from various manufacturers

print speed

up to 500mm/s*

dispensing speed

up to 60 m/min**

up to 400 mm/s with dispensing edge

Backing Width

with 4" device - 120 mm

with 6" device - 180 mm

roll diameter

300mm (default)

300 mm (with powered unwinder)

450 mm (with powered unwinder)

core diameter

40mm | 76mm (default)

76mm with quick release

(with powered unwinder)

connectivity

product light barrier

10 pin Interface (customer interface)

3-stage signal light

Expansion module for I/Os

steering

Siemens S7-1200 or microprocessor control

service

KTP400 basic | TP700 at Siemens control

2-line display | 8.4" touch panel with microprocessor control

Other features

built-in EMERGENCY STOP relay

(2-channel)

signal exchange

digital I/Os and/or PROFINET (optional)

Approvals***

CE | UL

*depending on the selected print module

**depending on the selected application module

*** depending on control type